The very first cargo ships were built to carry cargo in bulk. Even in most general cargo ships, wooden containers or boxes were used to stow unit cargo. But, with the inclusion of wider types of cargo, containerisations was deemed suitable for compact, fragile, and cargo requiring special care during transit. Hence, was felt the need to design special types of ships that could not only be loaded with these containers, but were also able to maintain the safe conditions of the contents of the containers.

In this article, we will discuss the design aspects of container ships. It is important to understand, from this article, how the design of a particular type of ship is dictated by the type of cargo, the ports on route, the functionality of the ship, and also the economic trends in the market. Also, before understanding container ships design, it is advised that you have a basic knowledge of fundamental ship terminologies, and those related to hull geometry (e.g. Block coefficient, Midship area coefficient, etc.)

Container Ships Design And Construction

There are different categories of container ships, based on different ways in which they can be categorised. The most widely operating types are as follows:

Based on overall sizing-

- Based on volumetric capacity (In older days, container ships were sized based on their volume)

- Based on TEU (This is the modern day sizing parameter of a container ship. The TEU of a container ship is the number of twenty foot equivalent containers that can be carried by the ship.)

Based on Length, Beam, Depth, and Tonnage-

- Panamax

- Post- Panamax

- Suezmax

- Post- Suezmax

- Malacamax

Based on mode of handling-

- Box container ship – This is the most common type of container ship design. They can be loaded only with marine containers, and cargo handling is carried out by quay side cranes that belong to the port authorities. Such ships always ply only on major container ports that are equipped with cranes.

- RORO ship – On roll on / roll off type of container ships, containers are rolled on and off the ships using heavy lift vehicles and fork lift trucks. These type of ships, in some cases, carry both vehicles and containers in different decks.

- LILO ship – Lift on / Lift off ships are equipped with their on cranes which are used to load the containers on and off the ship. These ships always ply only in smaller container terminals that are not equipped with container handling cranes, like the bigger terminals.

Based on Range of Service-

- Mother Ships – These are the larger ships, often above 10000 TEU capacity, that ply only between the major container terminals of a nation. These ships cannot enter smaller ports due to their large draft and overall size.

- Feeder Vessels – Feeder vessels operate between the major and minor container terminals, carrying containers to and from the mother ships. Often, these vessels are LILO type, because smaller ports are not equipped with quay-side cranes.

Container Ship Design – The Hull Geometry:

The first and the most prominent design aspect of any type of ship is the geometry of its hull. Before we understand why hulls of container ships have attained their characteristic shape, we should first notice the geometry itself. A visual comparison of the hull of a container ship with that of a bulk carrier or an oil tanker would clearly imply that a container ship’s hull has a finer formthan the other two. In other words, the forward and aft sections of a container ship are streamlined, and not fuller like that of a bulk carrier or oil tanker. Why?

Image for Representation Purpose Only; Credits: wikimedia.org

To answer that, we will need to first understand another aspect of the container industry. Goods shipped in containers are often of high value, and high priority. For example, if a marine diesel engine for a ship being constructed in a shipyard in India is to be shipped in from Germany, the shipment would be made in a container, and is a high priority shipment because the installation of the engine into the engine room is a step in the construction process that would determine the possibility of delays in the later stages of construction. Also, the equipment needs to be delivered without any impact or damage. Thus, container ships are tightly time bound ships. They have a very low turnaround time, that is, the time they spend at a port for loading and unloading has to be minimum in order to be able to call the next port without delay. It is due to this reason, container ships fall in the category of high speed ships. In order to achieve a high speed, the resistance of the hull needs to be minimized, which is obtained by a fine form hull. In other words, container ship hulls have low coefficient of buoyancy, ranging from 0.6 to 0.7.

Another notable geometrical characteristic of container ships is the high prismatic coefficient of the hull-form. That is, the hull section for most part of the length of the ship is almost rectangular. This is done in order to accommodate maximum number of containers below the deck.

Midship Section Of Container Ships:

One of the most important structural drawings that are prepared during the design of a container ship is that of the midship section. The midship section of a ship is prepared with a lot of design and functional considerations in mind, which include the type of cargo, stowage methods to be used by the ship, capacity of the ship, etc. In fact, a ship type is often identified by its midship section.

For a typical container ship design, the midship section is shown in the following figure. What is however important, is to understand the drawing from a designer’s point of view. Some common features of the midship section of a container ship are discussed below:

- All container ships are double bottomed, so as to allow for the double bottom spaces to be used as tanks.

- Container ships are also longitudinally framed, because the variable loading conditions often result in large hogging and sagging moments, which result in high longitudinal bending stresses.

- The shape of the midship section is almost box-like. In the words of a designer, it has high midship area coefficient, ranging from 0.75 to 0.85

- The bilge strake is the angular plate that joins the inner side shell and the tank top plating. Since the presence of this plate would prevent the stowage of containers at the corner of the section, the length of this strake is kept to a minimum. In most recent cases, however, container ships are not provided with bilge strakes at all, in order to ensure maximum stowage capacity.

- The most important structural feature of a container ship is the torsion box, which we will discuss in detail in one of the following sections.

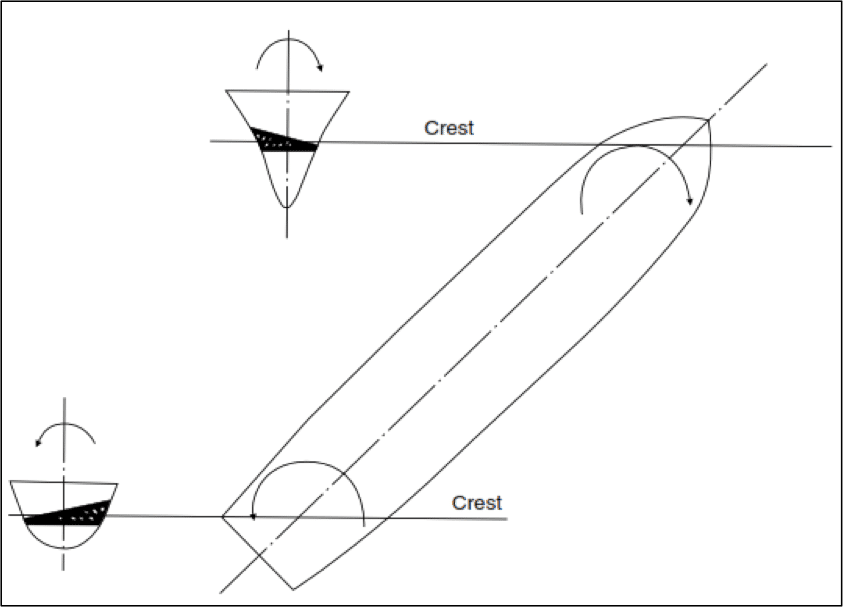

- Container ships are usually equipped with no hatches. That is, the ship has no continuous main deck running full breadth all along the ship. This open box-like structure (relate with the midship section figure), enables easy stowage of containers from the tank top to the highest level above main deck level. The only decks are within the double hull, which are more like stringers running full length, and provide passage way along the length of the ship.Torsion Box In Double Hulled Containerships:Let us start by recalling the shape of a water bucket. You would have noticed that the rim of every water bucket is always twisted outward. Why do you think this is done?Try cutting off the rim of the bucket, or for that matter, cut off the rim of a paper cup and try holding it with some liquid in it. You would notice that the paper cup would not resist the torsion. It would twist and eventually rupture. This happens because the entire structure of a bucket or a paper cup or any open box has a very low polar moment of inertia. This results in giving it a very low torsional strength. Thus, in order to strengthen open box like structures against torsion, additional material is added to their rims. In other words, one simply increases the polar moment of inertia of the cross section of the structure. But how is this related to a container ship?We know that the hull of a container ship is an open box like structure. When a ship is at sea, it is subjected to various wave loads. In one of the load cases, when the direction of the waves is at approximately 45 degrees to the velocity of the ship, port side of the forward section and the starboard side of the aft section would experience a wave crest at the same time, and vice versa. This results in a type of periodic loading which causes the hull to twist. This effect is called torsion, and is shown in the following figure.Fig. Torsion in a container ship moving in quarter seas.Imagine the effect of cutting the strengthened rim off the paper cup. The same effect when extrapolated to that of a container ship, would result in devastating failures of the hull structure due to torsion. In order to prevent this, the topmost edges of the port and starboard sides of a container ships are strengthened with high scantling web sections, creating a box like structure at every frame. This is called torsion box. A torsion box runs along the entire length of the ship from the aft peak bulkhead to the forward collision bulkhead.The following figure shows the torsion box of the double hull container ship. Note that the width of the web plate in the torsion box is higher than the web plate used around the passage way below it. Also, the webs at passageways are at a spacing of three to four frame spaces, but the webs of a torsion box would be present at every frame.

No comments:

Post a Comment